Ballast Level and Fouling Inspection

Ballast is used to transmit and distribute the load of the track and rolling equipment to the subgrade, restrain the track laterally, longitudinally and vertically, facilitate drainage of water, maintain proper cross level, surface, and elevation, as well as inhibit the growth of vegetation.

Ballast can degrade in condition and become less effective over time. and can also become fouled due to the fracture and abrasion of ballast particles, infiltration from underlying layers, and spillage from containers in transport. Fouled ballast can result in poor drainage and ultimately track surface deviation due to increased layer stiffness.

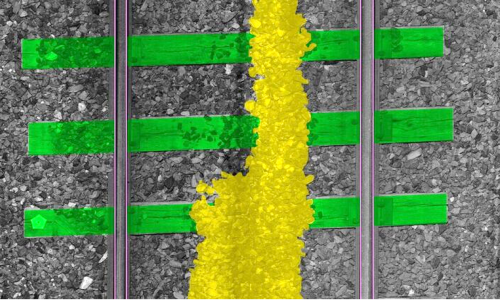

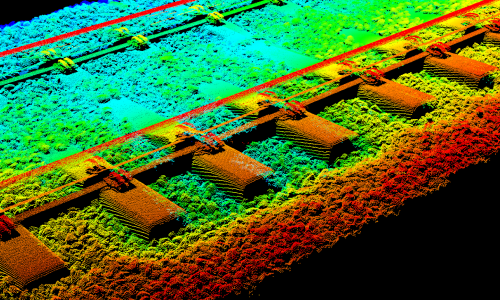

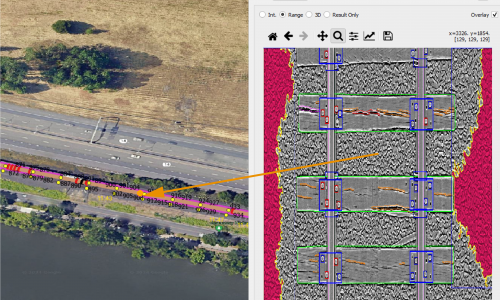

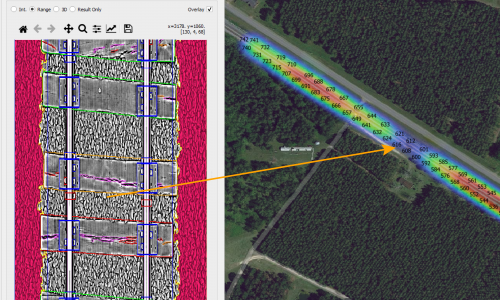

Pavemetrics’ LRAIL simplifies the task of ballast inspection by using Artificial Intelligence to analyze both 2D and 3D data in order to precisely and objectively measure ballast height and ballast fouling. Ballast height is automatically measured at the end of ties as well as in the crib area and locations with deficient or excessive ballast levels can be flagged. Ballast fouling can also be automatically detected and quantified objectively.

Standard

49 CFR § 213.233 – Track inspections

Related Articles

Laser Triangulation for Track Change and Defect Detection

Authors: Federal Railroad Administration

Laser Triangulation for Track Change and Defect Detection

Authors: Federal Railroad Administration