LDTM fournit des modèles topographiques 2D et 3D de qualité géomètre à vitesse autoroutière — en un seul passage fluide.

Voir la fiche technique (Anglais)

Résolution de 1 mm sur toute la largeur d’une voie de 4 m.

Collecte jusqu’à 45 millions de points par seconde à des vitesses pouvant atteindre 100 km/h.

Combine images 2D, profils 3D, GPS et IMU pour une précision inégalée.

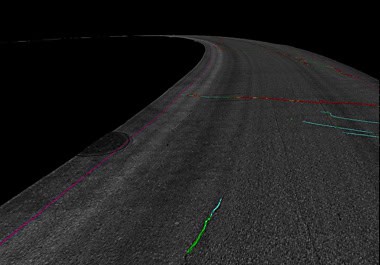

Génère automatiquement lignes de rupture, bordures, accotements, pentes, dévers et plus encore.

Basé sur la plateforme LCMS® de Pavemetrics, largement déployée avec plus de 100 unités dans le monde.

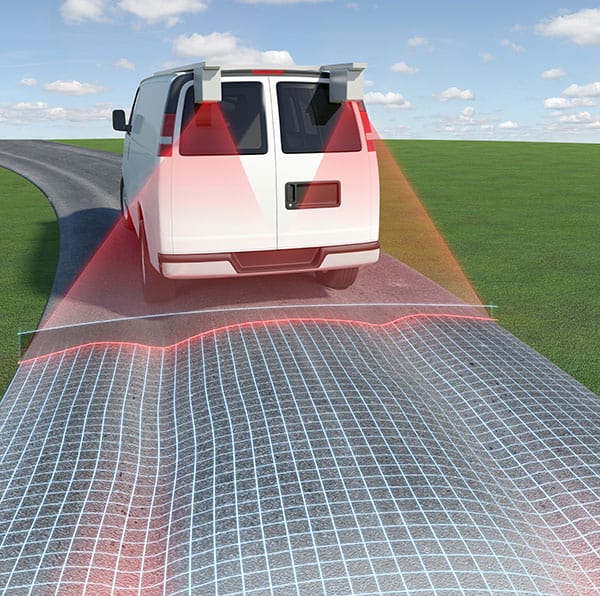

Le Laser Digital Terrain Mapping System Pavemetrics® (LDTM) utilise des projecteurs laser linéaires, des caméras haute vitesse et une optique de précision pour acquérir des profils 3D haute résolution de la surface de la route. Combiné à un GPS et à des unités de mesure inertielle (IMU), le système corrige les mouvements du véhicule et géoréférence avec précision chaque balayage.

En un seul passage, le LDTM acquiert simultanément des images 2D et des nuages de points 3D, qu’il fusionne de manière fluide pour créer une carte numérique du terrain à haute précision.

produit des lignes de rupture précises directement à partir des données 3D.

identifie tous les éléments clés de la chaussée en un seul passage.

assure une performance fiable quelles que soient les conditions d’éclairage.

conception efficace optimisée pour les véhicules d’arpentage.

capture des détails au millimètre sur toute la largeur de la voie.

fournit l’ensemble des paramètres géométriques de la chaussée.

fournissent des cartes altimétriques de qualité topographique.

capture jusqu’à 45 millions de points par seconde.

garantit une couverture dense et haute résolution.

offre un niveau de détail précis sur toute la largeur de la voie (4 m).

Authors: Richard Fox-Ivey, John Laurent and Benoit Petitclerc (Pavemetrics)

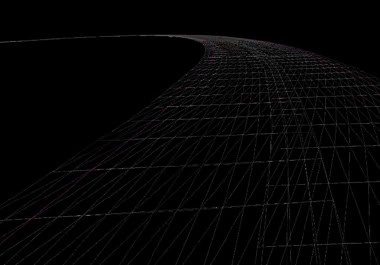

Abstract: State departments of transportation (DOTs) typically perform annual pavement condition inspections, which serve as an important input into pavement management systems (PMS) software. Road surface defects (cracking, rutting, smoothness, etc.) are analyzed by PMS software to model the deterioration of pavements and to make budget and performance-based recommendations about which roads to maintain and how and when to maintain them. Increasingly at the state DOT level, these data are captured using high-speed 3D lasers (laser triangulation systems) that acquire the 3D shape of the road surface to evaluate its condition. Traditionally the capture of road elevation data relied entirely on the use of survey crews. Although accuracy can be quite high, the process of capturing elevations can require a lot of manpower, is time-consuming, requires lane closures, and results in a relatively small number of points per kilometer of road with which to perform all of the tasks from early project planning through construction. This paper explores an alternate approach that leverages existing 3D laser technology utilized by DOTs to measure the condition of in-service pavements. Typically, these laser systems capture ''relatively referenced'' 3D profiles of the roadway to evaluate pavement condition based on surface distortion. However, there is often no connection between these ''relative'' 3D profiles and real-world locations. This new approach involves the addition of high-accuracy blended global navigation satellite system + inertial navigation system positioning systems, as well as specialized software, to map the absolute position of 3D profiles in real-world coordinates.

Authors: John Laurent, Richard Fox-Ivey and Benoit Petitclerc (Pavemetrics)

Abstract: Road Transportation and Public Works Departments (DOTs) typically perform annual pavement condition inspections to record cracking, rutting, smoothness, etc., which serve as an important input into Pavement Management Systems (PMS) software. Road surface defects are analysed by PMS software in order to model the deterioration of pavements and to make budget and performance-based recommendations regarding which roads to maintain, what maintenance treatments to apply, and when to apply them. Increasingly pavement condition data are captured using high-speed 3D lasers which acquire the 3D shape of the road surface. These technologies automatically analyse 3D scans in order to detect and quantify pavement defects. There is an untapped opportunity to enhance and repurpose this data in order for it to also be used for the design of reconstruction projects. In the past, designers have relied upon traditional survey to capture elevation data for volumetric estimates as well as Preliminary and Final Designs; however, traditional surveys require lengthy road closures, are costly, limited in resolution, and present dangerous working conditions for survey staff. Alternatively, 3D pavement condition survey scans can be enhanced through the addition high-accuracy Latitude, Longitudinal and Elevation data (via "blended" GNSS + INS systems). When further processed, these 3D scans can provide elevations with comparable accuracy and repeatability to traditional methods, but for a significantly larger number of measurement points (as dense as a 1mm x 1mm grid), without the need for a road closure, in a fraction of the time. Thus, repurposing these data presents a significant opportunity for DOTs to reduce their survey costs, minimize traffic interruptions, decrease turnaround times, improve staff safety, reduce milling, paving and compaction quantities, and deliver superior road surfaces. This paper explores the necessary hardware and software as well as the steps required to generate high-accuracy elevations from 3D pavement scans. Importantly the accuracy and repeatability of this new method is thoroughly evaluated through direct comparison to a large network of surveyed control points.

Authors: Benoit Petitclerc, John Laurent and Richard Habel (Pavemetrics)

Abstract: This article proposes a way to reuse the 3D road surface condition data to create road surface model and avoid expensive manual road surface surveys that require road closures. This new approach provides a way to tag collected high resolution high accuracy transverse road profile data acquired by a LCMS system (Laser Crack Measuring System – Pavemetrics) with a highly accurate GNSS-INS system (Applanix POS-LV – Trimble) to measure both road surface condition and to generate a survey grade accuracy terrain map of any road surface. The information provided by the 3D LCMS system, DMI, Applanix POS-LV, GPS with local RTK corrections and post processing (POSPac-Trimble) software are used to generate the road surface models with repeatable measurements and accuracy compared to surveyed control points. This process results in significant productivity improvements, optimization of the quantity of material that needs to be carried in and out, lower survey costs, decreased traffic interruptions and improved safety of surveyors while improving the quality and resolution of the road surface models.