Scan entire tunnel linings at highway speed with unmatched 2D/3D millimeter accuracy.

LTSS delivers fast, reliable, and automated insights for safer, smarter infrastructure decisions.

High-speed tunnel scanning at up to 50 km/h with minimal operational impact.

Capture the entire tunnel perimeter in a single pass, with scalable sensor configurations.

Millimeter-resolution 2D/3D data that’s up to 10× more accurate than typical LiDAR.

Automated software identifies cracks, joints, degradation, and water ingress.

Trusted on major tunnel networks worldwide for consistent, repeatable results.

The Pavemetrics® Laser Tunnel Scanning System (LTSS) is a high-speed 3D vision solution that automates full-vault tunnel inspection with millimeter precision. Using multiple synchronized laser scanners, LTSS captures both 2D imagery and high-resolution 3D profiles of tunnel linings — all at speeds of up to 50 km/h.

Designed for rapid, large-scale tunnel assessments, LTSS scans up to 12 meters of tunnel perimeter in a single pass, delivering consistent, repeatable data that is 100× faster and 10× more accurate than typical LiDAR. Larger surfaces can be covered through stitched passes or expanded further with additional sensors, making the system fully scalable to any tunnel geometry.

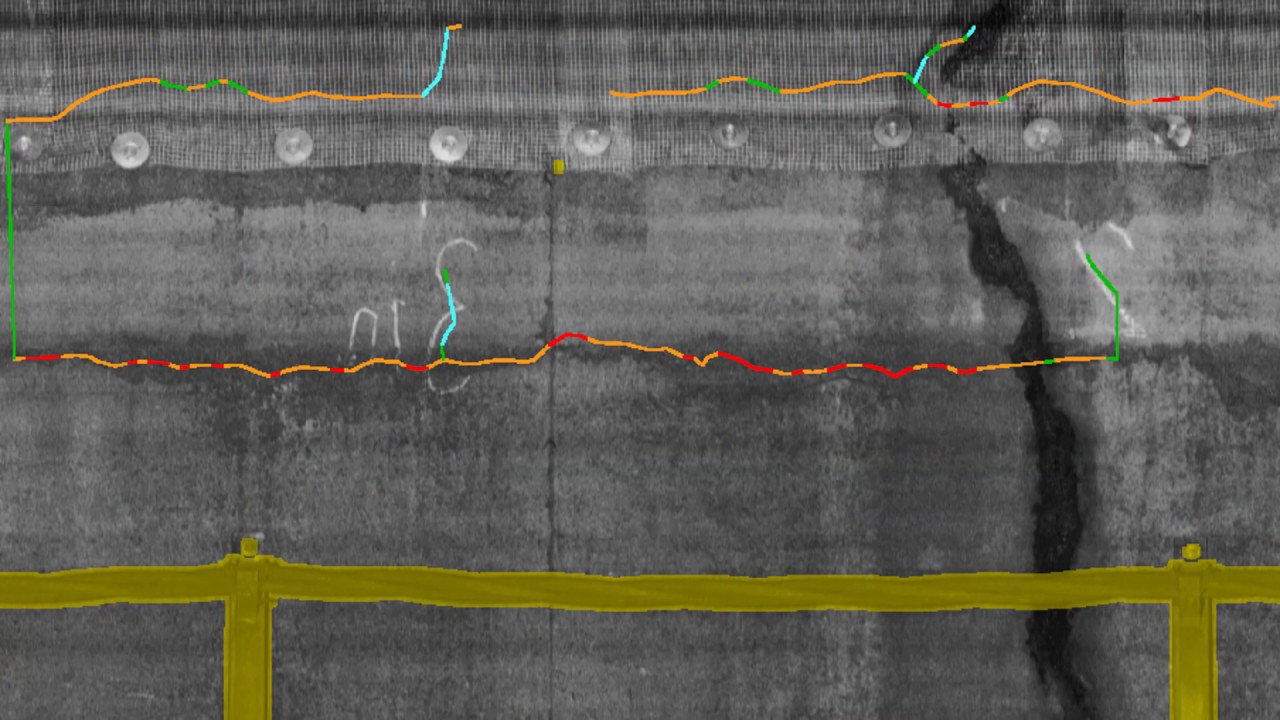

Once digitized, tunnel data can be analyzed offline using advanced multi-resolution 3D software that enables precise measurement of virtually any structural feature. Automated analysis tools are also available to detect and rate cracks, joints, faulting, concrete degradation, and areas of water infiltration — providing agencies and operators with actionable insights to extend asset life, prevent failures, and optimize maintenance planning.

Scan full tunnel vaults at up to 50 km/h with millimeter resolution.

Capture up to 12 m of tunnel perimeter in a single pass, with scalable sensor configurations for larger geometries.

Acquire 120M 2D/3D points per second with 0.5 mm vertical accuracy — up to 10× more accurate than typical LiDAR.

Extract precise dimensions of structural elements, joints, linings, and surface defects directly from 1-mm-resolution 3D data.

Software available to detect cracks, joints, faulting, degraded concrete, and water/wet-area ingress — with condition ratings.

Review 1-mm-resolution surface details and measurements from any point of view without leaving the office.

Successfully deployed in major tunnel systems worldwide, including the 28-km Guadarrama high-speed rail tunnel (Spain) and Tokyo Metro (Japan).

Extensions available for voussoir-type tunnels, expanded scanning width, and rail-specific acquisition.

1 mm 2D/3D data across full vault

0.5 mm vertical accuracy

0–50 km/h

30,000 Hz

Up to 120,000,000 3D + 2D points per second

Standard 6-sensor configuration (expandable)

12 m tunnel perimeter in a single pass

Multi-resolution 3D models, 2D imagery, and analysis-ready formats

Concrete linings, voussoir-type tunnels, rail tunnels, metro systems

Authors: John Laurent (Pavemetrics), Richard Fox-Ivey (RFI Consulting Services), Fernando Sanchez Dominguez (Euroconsult Group), José Antonio Ramos Garcia (Euroconsult Group)

Abstract: This presentation will explore the application of 3D laser scanning technology to the activity of tunnel inspection. The discussion will include a discussion of the practical achievable levels of data precision and accuracy obtained during testing the Guadarrama and Regajal rail tunnels in Spain.

Authors: M. Gavilán, F. Sanchez, J.A. Ramos and O. Marcos (Euroconsult Group)

Abstract: This paper presents a novel system for tunnel lining inspection, Tunnelings, which allows for high-resolution surveys at speeds up to 30km/h. This rapid tunnel condition assessment capability makes it possible to perform long tunnel inspections on a regular basis, and to assist geotechnical engineering and tunnel management, allowing for preventive and operational maintenance of large infrastructures. Tunnelings uses several laser-cameras units and acquires intensity images and 3D profiles with an accuracy depth of 0,5mm and a longitudinal and transverse resolution of 1mm. The laser-cameras units can be installed on a bimodal (road-rail) all-terrain truck which provides rapid travel speeds and flexibility to cope with different types of tunnels and infrastructures. Moreover, they can also be installed on other kinds of vehicles, as well as in a standard railway wagon. A computer vision-based software helps with the evaluation of the tunnel condition, allowing for the detection of cracks and areas with missing lining or chipping, dampness and running water, areas with poorly assembled segments, protruding edges and poor workmanship, as well as the assessment of tunnel installations.